Our Products

Large Prismatic Battery Components

We are engaged in the production of large prismatic battery components for electric vehicles (xEV) and fulfil orders according to various requirements. We apply ultra-precise welding technology to produce multi-tab type components, which not only helps increase performance but also prevents battery bursting and maximises electrolyte storage capacity. To increase the battery performance of electric cars, we have developed a new integrated forming type and further developed aluminuim surface treatment and injection processes.

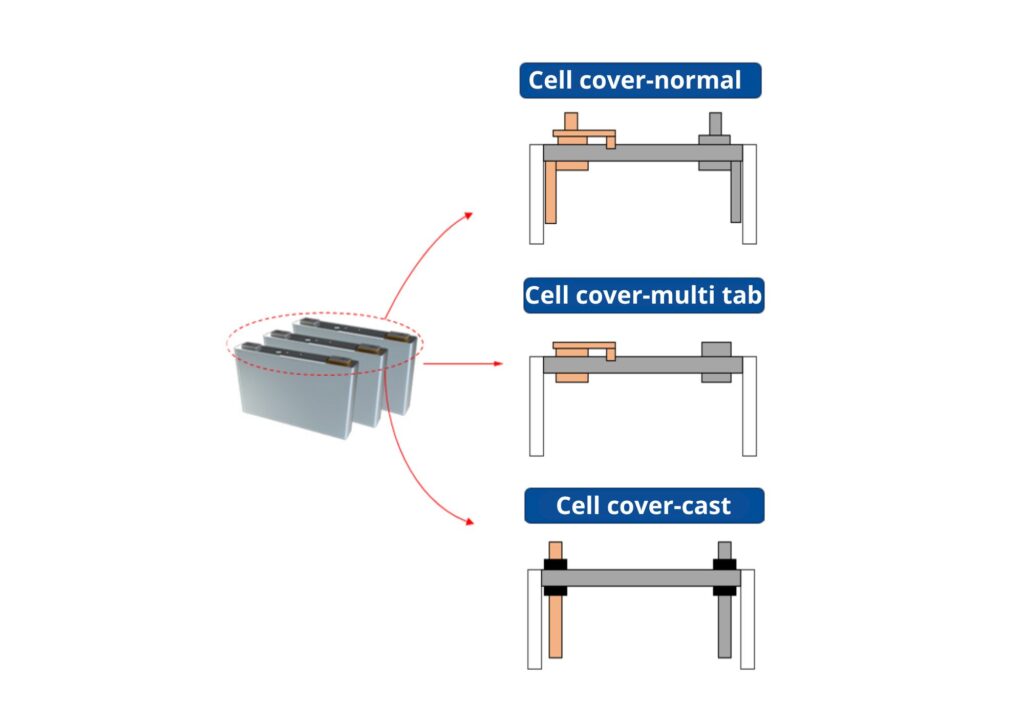

Cap Assembly

Technology

Casting Press

- Design, tool design: Components produced by pressing.

- Design based on various standards for energy storage in electric vehicles, utilising appropriate casting techniques and expertise.

- Material costs are reduced thanks to decades of expertise and ultra-precise technology.

- Our precision machining pressing technology meets the strict requirements for product quality.

- Professional production of cap plate, vent, and membrane plate.

Automated Assembly

- Cost competitiveness and increased production capacity thanks to our in-house designed automated manufacturing equipment.

- Efficient operation of a large number of automated assembly lines, appropriate expertise to operate mass production.

- Safe, ultra-precision laser welding technology for assembling precision press components.

Injection Moulding

- We perform plastic injection moulding on pressed components using our own developed technology.

- Increased tensile strength and clamping ability through chemical surface treatment and intaglio etching.

- Cost-effective and competitive process ensured by simplified casting of components.

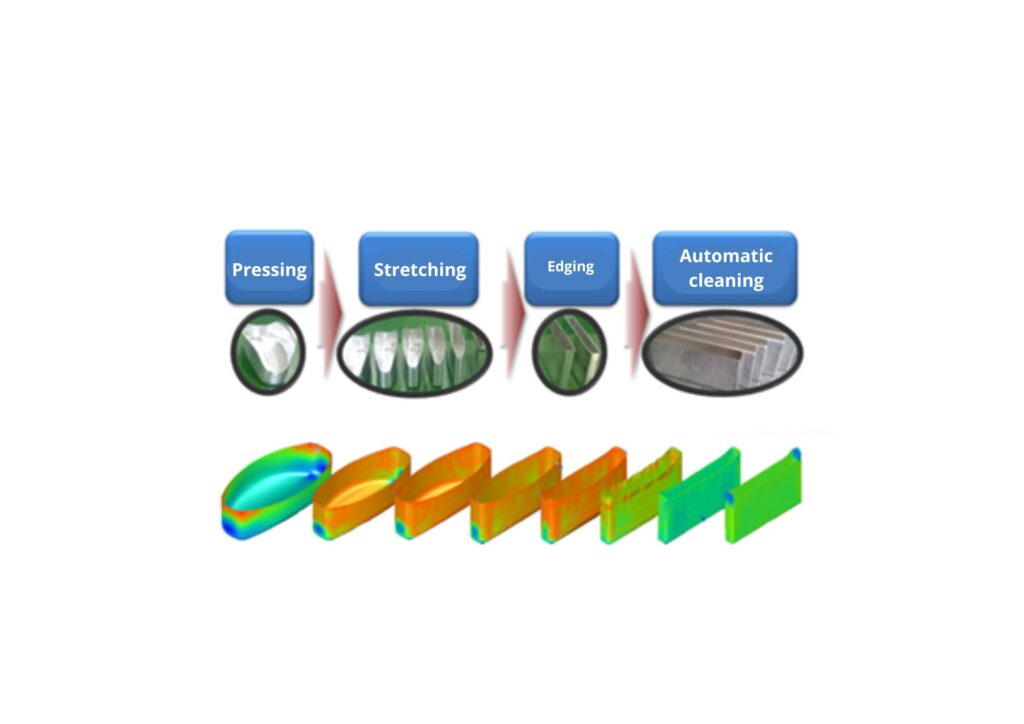

Large Prismatic and Polymer Element Components

To effectively manufacture CAN, we maximise production efficiency with casting analysis technology and a one-step deep drawing press process.

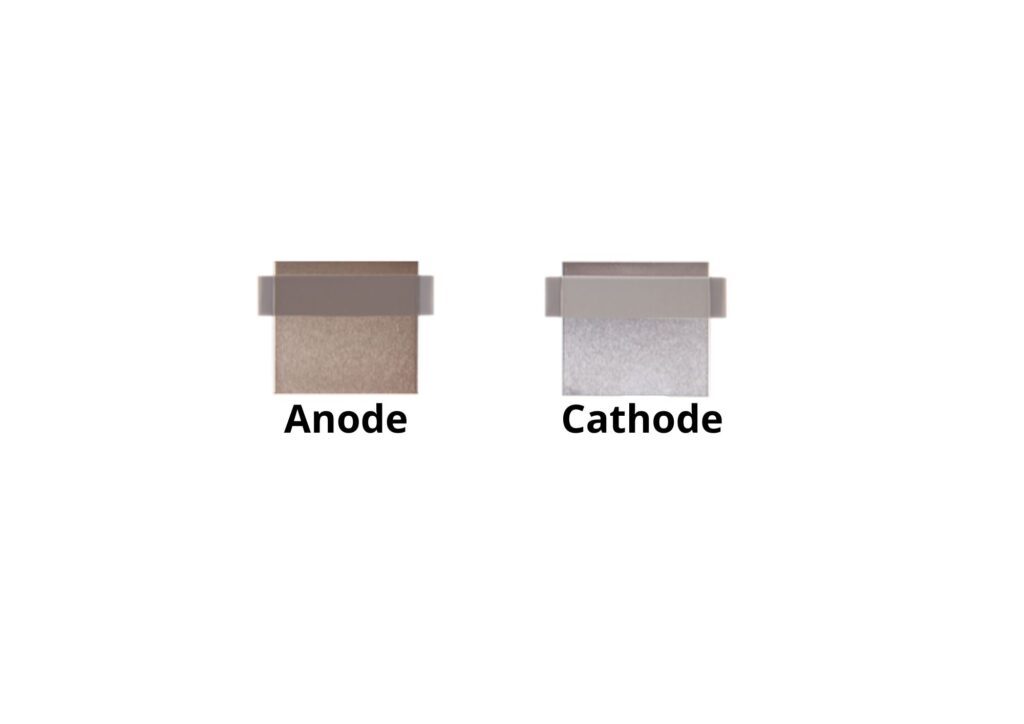

We develop large terminal strips for electric vehicles (xEV) based on our own small terminal strip technology, allowing us to enter the polymer battery manufacturing market, which covers a significant portion of xEV batteries. Our innovations contribute to diversifying the market and increasing its quality.

Technology

Terminal Connector Product

Quality

Quality assurance plays a vital role in manufacturing to maintain the excellent level of products and processes. Its goal is to guarantee compliance with manufacturing standards and regulations, and to ensure the production of flawless and reliable products. To this end, quality assurance monitors manufacturing processes, inspects materials and components, and intervenes promptly if issues arise. Its task is also to continuously improve processes, reduce the number of rejects, and ensure customer satisfaction.

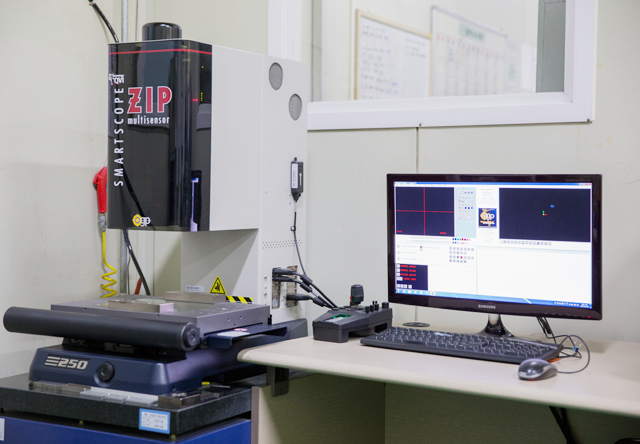

Measuring Instruments

3D Measurement

High Temperature and Humidity Testing